How to Achieve Perfect Finish on Plastic Parts

Achieving a smooth surface finish on machined plastic part is important because it affects the part’s visual appearance, functionality, and durability. In many cases, the surface finish is the first thing that people notice, so it is important to make a good first impression. Functionally, a smooth surface finish can help to reduce friction and improve the performance of plastic parts. Additionally, a smooth surface is less likely to accumulate dirt and dust, which can lead to contamination and wear. Finally, a good surface finish can help to protect the part from scratches and other damage. Several tips can be implemented to improve the surface finish of plastic parts, which are exactly what is going to be covered in this post.

Reasons of Poor Surface Finish on Plastic Parts

Plastic parts without a good surface finish can cause a lot of problems in their further manufacturing processes. Poor surface finish can lead to greater manufacturing costs, as well as declined product quality, along with shorter product life cycles. In order to mitigate these problems, it is important to understand the root causes of poor surface finish and take steps to correct them.

Some of the most common causes of poor surface finish in plastic parts include:

- Incorrect part design

- Incorrect material selection

- Improper manufacturing processes

- Inadequate post-processing

Tips to Improve Plastic Parts’ Surface Finish

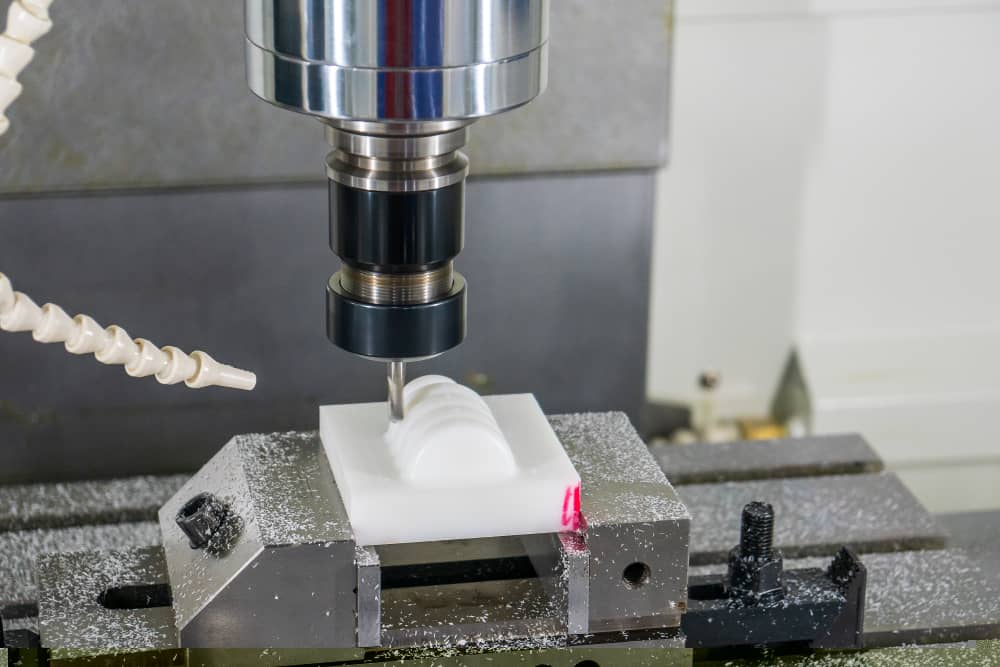

The surface finish of a machined plastic part is a combination of the tool geometry, cutting conditions, and plastic properties. In order to get the best possible finish, there are several things that need to be taken into account. A few of them are;

Use the right type of tool for machining:

A high-quality tool will produce a better surface finish, irrespective of the complexity of the machining operations.Choose the right plastic material:

The type of plastic material being used is one of the most important factors. Some materials are more prone to scratching and blemishes than others. Choose materials that are better suited for machining, and that are known to produce a smoother surface finish.Choose the right cutting parameters:

The cutting parameters like speed and feed rate must be set appropriately If these are not set correctly, it can cause the tooling to chatter and produce a poor surface finish.Use a Sharp Tool:

A sharp tool has a small cutting radius and results in a smooth surface finish. The cutting tools and the way they are used also play a role in determining the quality of surface finish. If the tool is too sharp, or if it is used too aggressively, it results in a poor-quality finish.Use a proper cutting speed:

The speed and direction of the cut also plays a role in the surface finish of the part. A high cutting speed can cause excessive heat and lead to a poor surface finish.Use Correct Feed Rate:

Another method that can be used to improve surface finish is to use the correct feed rate. The feed rate is the speed at which the workpiece is fed into the cutting tool. It is important to use the correct feed rate in order to avoid damaging the workpiece.Use the right surface finish blasting process:

This will differ as per the properties of the plastic materials. This can be done using a variety of media, such as sand, glass beads, or aluminum oxide. Choose the one wisely to achieve a smooth and shiny surface finish.Employ the Chemical Finishing Process:

Another common method for improving surface finish is to use a chemical polishing process. In this process, a chemical is applied to the part surface, and then a polishing wheel is used to polish the part.

Overall, the surface finish of a machined plastic part is determined by a number of factors, such as the type of plastic, cutting tool material, cutting tool geometry, and machining conditions. In order to achieve a good surface finish, it is important to optimize all of these factors.

When it comes to precision plastic machining, surface finish is key. In order to ensure a smooth and blemish-free final product, it is essential to partner with a service provider that has expertise in this area. China CNC Machining specializes in precision machining and finishing of plastic parts. Our team of experts utilize a variety of finishing techniques to achieve the perfect surface finish for your project.