Technical Drawings for CNC Machining – What’s and Why’s Answered

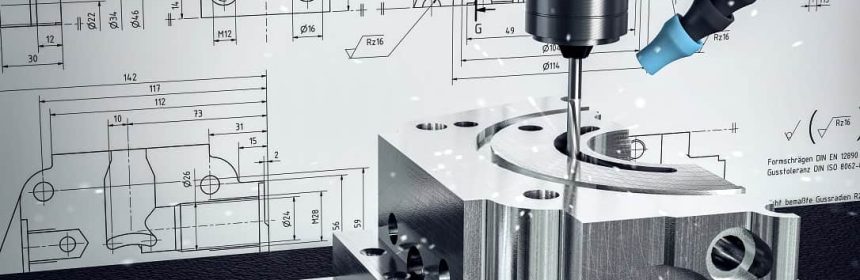

Computer numeric control (CNC) machining is one of the most popular methods in use today for sheet metal and plastic fabrication. There are many CNC machining techniques that help create precise customized machined parts with correct dimensions, optimum strength, and tight tolerances or as required. Owing to the technological advancements in machining and their compatibility and flexibility with several materials, there has been tremendous growth in their usage over the years. CNC machining is an automated machining process, where machining tools are driven by software programs, and their designs are created using 3D modeling software such as CAD. These designs or technical drawings are an important step in the entire process as the parts are machined based on the drawing. Is that all? No, there’s more to it. You may want to know what makes technical drawing an integral part of CNC machining. This post aims to answer this question and more.

Importance of a Technical Drawing Analyzed

Technical drawing or part design as a segment is very old and was done manually for centuries. Now, the process can be automated through design software. Technical drawings serve as an interface or a communication bridge between the designers and the mechanist or machine operators. Technical drawings, popularly named engineering drawings, contain detailed 2D, and now even 3D, information of the part to be manufactured, along with the important manufacturing data, such as material and finishing requirements, part usage, dimensions, shape, size color, surface finish, and much more. In many cases, the machinist can manufacture a part with only the help of a technical drawing to get the right output.

As discussed earlier, technical drawings are one of the important base steps for creating of 3D models in CNC machining. The role of technical drawings is as follows:

- While the 3D CAD design is useful for pre-programming the machine with the required commands, a technical drawing is useful for detailing. For instance, most parts such as screws and nuts have threads on them which is needed to be viewed in detail to get them right on a physical level. The same applies to surface finishing of various surfaces of the part. Technical drawings depict these features effectively.

- Technical drawing an isometric view as well as a detailed section-wise view. This makes it easy to understand critical information such as tolerances, annotations, dimensions, and much more. With the aforementioned information, the machinist understands and fine details of the parts to be produced.

- Hole drilling in the right slot, especially for PCBs and various other parts is a crucial aspect of CNC machining. Technical drawings help understand depth, sinks, and other details.

Different Components of Technical Drawings

Technical drawings typically comprise the following important components. So, let’s have a look at them.

- Title Block: It is placed in the bottom right corner of the document. It comprises the basic information of the parts to be produced, such as the name of the part, part number, company name, material and finishing requirement, drawing number, and much more. In addition to this, it also contains the technical information of the part, such as system measurements, angle of projection, surface finish requirements, scale, and material.

- Isometric View: Popularly known as a pictorial view, it provides the 3D representations of the part to be produced. This helps the reader to virtually understand the part quickly. Isometric views combine the illusion of depth with the undistorted presentation.

- Orthographic View: Also known as primary view, this is a two-dimensional representation of the three-dimensional object from the top, bottom, left, right, and rear end. This view emphasizes dimensions and features. The geometry of many parts can be described using two or three orthographic views.

- Coordinates: They are reference points in complex technical drawings. They are placed along the borders of the drawing to visualize the parts neatly.

- Section View: It is a 2D representation of the part when it’s cut through. This view shows the internal features of the parts, which are not visible in both the orthographic and isometric views. These views are characterized by a cross-section along a specified cut plane.

- Detail View: It shows the complicated areas of the orthographic view.

Step-by-Step Guide on Preparing Technical Drawings for CNC Machining

Here are a few essential steps to complete while drafting technical drawings for CNC machining. So, let’s have a look at them.

- The first and foremost important step is to define views as per the requirement. Next, keep orthographical projection in the drawing center, leaving appropriate space for dimensions.

- Try to utilize section or detail views if the parts have internal features or difficult to access areas.

- Create construction lines for all views. This may include center lines, center marks, and center mark patterns.

- Create dimensions to your drawings.

- Determine the size, length, and location for all threads.

- Apply standard tolerances to all features

- Fill in the required blocks and relevant information correctly.

Note: Make a note of any information or requirement that exceeds the standard practices.

In addition to the information mentioned above, it is important to specify dimensions, annotations, and tolerances for technical drawings. The following section describes all these pointers in detail.

Proven Tips for Adding Dimension, Tolerances, and Annotations

Once done with parts designing with a 3D CAD file, OEMs face difficulties checking the dimensions on technical drawings. The following are some essential tips that help dimension the model. This will also help reduce some severe manufacturing errors.

- Place dimensions of all relevant parts.

- For functional purposes, add critical dimensions to all parts.

- Add dimension to other features too. It should be placed correctly on views with clear and readable descriptions.

- Add only one dimension for repeated features, and specify the total number of repeat features in the current view.

Specifying Tolerances in Technical Drawings

Tolerances in technical drawings are defined as the acceptable range of dimensional variation. This feature is vital for feature interference of two components. Tolerances are classified into different formats and can apply to any dimension on technical drawing. Bilateral tolerances are the most popular and simplest of types. They are symmetrical around the base tolerances as±0.1 mm.

Note: Technical drawings require tolerances only when the standard values exceed.

By now, you may have got an idea about technical drawings and their role in CNC machining. Considering the aforementioned aspects of technical drawings certainly helps produce precise parts with ease, which ultimately leads to perfect end-use products. Any neglecting approach to technical drawings may lead to delays and also increase the overall production costs. To avoid this, it is always recommended to consult prominent CNC machining service providers in the market. You can consider China CNC Machining, a company with vast years of market presence and skilled employees which offers end-to-end CNC machining services for the most complex part designs.